The Industrial Electronics and Appliances industry relies heavily on complex cabling systems for various applications, including control systems, power distribution, and communication networks. These systems require precise and reliable wire connections, where wire stripping machines play a crucial role.

In the processing of industrial electronics and appliance cabling, wire stripping machines can quickly and accurately remove the insulation from wires, ensuring that each wire meets high-quality standards. This precise operation forms a critical component within modern wire harness automation. This not only improves production efficiency but also significantly reduces human error."

Wire stripping machines can process a large number of wires in a short time, greatly enhancing production efficiency.

The high-precision stripping function of wire stripping machines ensures the consistency of each wire’s quality, reducing the defect rate.

Automated wire stripping machines reduce the reliance on manual operations, lowering labor costs.

The Industrial Electronics and Appliances industry uses a wide range of cable types, including multi-conductor cables, shielded cables, and high-temperature cables. Wire stripping machines, often integrated with specialized upstream equipment like a core twisting machine, can handle these different types with ease.

Wire stripping machines ensure that the processed wires meet stringent industry standards and regulations, which is crucial in the Industrial Electronics and Appliances sector.

EW-3010+S Intelligent Software Controlled Wire Cutting Stripping Machine With Ink-Jet Printer(0.1-6mm²)

EW-3010+S Intelligent Software Controlled Wire Cutting Stripping Machine With Ink-Jet Printer(0.1-6mm²)

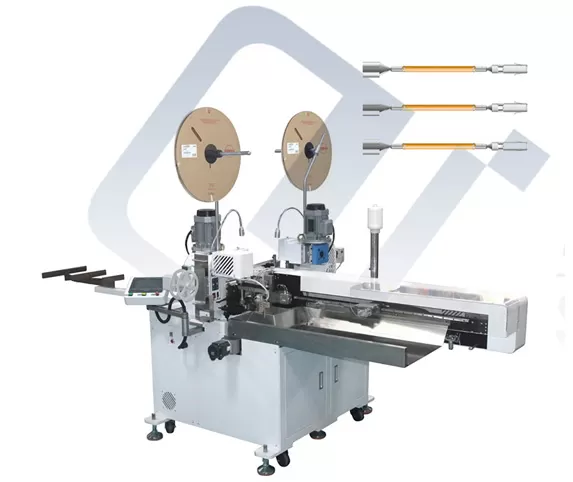

EW-22B Double-Crimping Automatic Terminal Crimping Machine

EW-22B Double-Crimping Automatic Terminal Crimping Machine

EW-3010+P Wire Cut Strip Machine with Ink-Jet Printer

EW-3010+P Wire Cut Strip Machine with Ink-Jet Printer

EW-9290 Automatic 5 8 Wires Double Side Crimping Single Side Crimping and Tinning Machine

EW-9290 Automatic 5 8 Wires Double Side Crimping Single Side Crimping and Tinning Machine