Model | EW-21C |

Applicable wire range | AWG34-AWG14 |

Stripping length | Side A:0-10mm, Side B: 0-13mm |

Cut precision | ±(0.5+0.002*L) mm, L=cut length |

Cutting length | 50-9999mm |

Capacity | 3100pcs/hour(L=200mm) |

Crimping force | 2.0T |

Air pressure | 0.6-0.8Mpa |

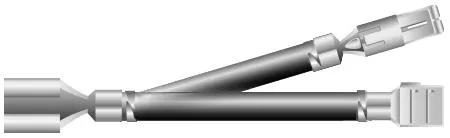

Function | Two wire both ends/ one end crimping/ Two wire crimp into on e terminal |

Detection | Wire run out, low air pressure, terminate error(Crimping force monitor is for optional) |

Power/Power Rating | 220V/110V/50/60HZ /3000W |

Display language | Chinese/English |

Dimension | 1600*800*1550mm |

Weight | 580Kg |

Foot pedal start | N/A |

Three crimping heads support combined (two wires into one terminal), individual end crimping, and cut/half-strip/full-strip recipes—covering most harness cell scenarios without secondary handling, thus streamlining complex crimp and seal production tasks.

Up to ~3,000 pcs/h at 50–100 mm; length tolerance ±(0.2 mm + L×0.002) under 100 mm and ±(0.5 mm + L×0.002) above 100 mm. Programmable blade depth with 0.01 mm resolution keeps strip quality consistent across lots.

Color HMI (EN/CN) stores job parameters; OTP-style straight/side-feed applicators swap quickly; stepper-based motion control and auto scrap-strip cutting reduce technician intervention and downtime.

Stable, compact, energy-saving design (W800×D1400×H1800, ~600 kg) runs on single-phase AC200–242 V with 0.5 MPa clean air; integrated sensors (air pressure, wire presence, crimp/feeding anomalies) help prevent defects before they escape.

We want to help you find the best option for your business. Tell us your needs by filling out the form below and we will contact you as soon as possible!