Model | EW-8285 |

Applicable wire range | AWG28-AWG18 |

Stripping length | Head:0-18mm,Tail:0-20mm |

Cut precision | ±0.1(0.1+0.003*L)mm, L=cut length |

Cutting length | 45-9999mm |

Capacity | 1300-1800pcs/hour |

Crimping force | 2.0T |

Applicators | 30mm or 40mm strokes for optional |

Air pressure | 0.4-0.6Mpa |

Detection | Wire run out, low air pressure, terminate error(Crimping force monitor is for optional) |

Power | 220V/110V/50/60HZ |

Display language | Chinese/English |

Dimension | 1700*920*1580mm |

Weight | 600Kg |

Power cord plug | European, USA, Chinese plug |

Full servo motors and screw rod drive enable ±0.1mm cutting/stripping accuracy with rapid movement.

Supports 45mm–9999mm wire lengths, 18mm (front)/20mm (rear) stripping depths, and 2.0T crimping force with 30mm/40mm stroke options.

Processes 1,300–1,800 wires/hour (100mm benchmark) across AWG28–AWG18, including electronic/high-temp wires.

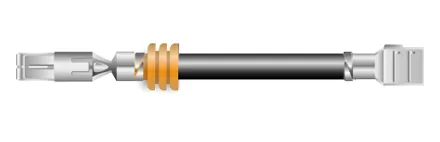

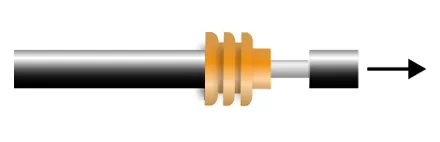

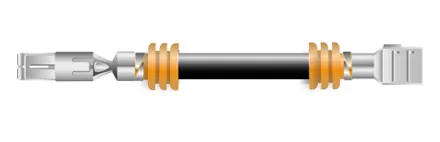

Patented waterproof plug insertion before stripping eliminates copper damage and boosts speed.

Auto-detects wire misalignment, air pressure faults, and crimping defects; segregates rejects instantly.

Optional CFM/CCD systems monitor crimp quality in real time with visual/curve analysis.

Bilingual touchscreen (Chinese/English) simplifies parameter setup and reduces training time.

Flexible add-ons (crimp force monitors) enhance reliability for high-volume batches.

We want to help you find the best option for your business. Tell us your needs by filling out the form below and we will contact you as soon as possible!