Model | EW-8815 |

Appearance size | L 1200*W 1100*H 1580 |

Weight | 500kg |

Placement space | 5m2 |

Power supply | AC220/50Hz |

Power | 3000W |

Air pressure | Within 6 kg |

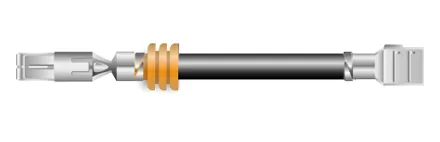

Terminal machine | Casting type precision terminal machine |

Suppress ability | 2T |

Rubber stopper transfer | Special rubber plug machine |

Display mode | Touch screen LCD display |

Function | Wire fixed length cutting and stripping, single end plugging, pressing end, tinning |

Applicable wire | Electronic wire, high temperature wire, halogen-free wire, Teflon wire, etc. |

Capacity | 1200~1700 pieces/hour based on 100mm length |

Applicable wire diameter | 30#-16# |

Cutting processing accuracy | Within ±0.1 (0.1 + 0.003 * L) mm, L = cutting length |

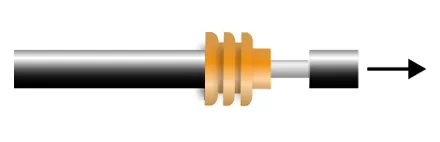

Peeling method | Screw rod independent stripping |

Minimum glue length | The glue left in the middle of the standard machine is 17mm (special non-standard can be shorter to 12mm) |

Peeling mouth length | The front stripping machine is within 15mm, and the rear stripping machine is within 18mm (variable) |

Tin dipping depth | 18mm(changeable) |

Waterproof plug insertion before stripping prevents copper damage and boosts speed, a key advantage in high-quality crimp and seal manufacturing.

Tinning module enhances conductivity/anti-oxidation (depth adjustable to 18mm), extending harness lifespan.

Independent screw-driven stripping (±0.1mm accuracy) with customizable mid-glue retention (12–17mm).

Cast crimping press (2T force) + ball screw translation ensures flawless terminal/wire alignment.

Real-time monitoring for stripping/crimping/tinning defects; auto-segregates rejects.

Corrosion-resistant components + horizontal roller feeding (pressure-adjustable) eliminate wire surface damage.

Bilingual touchscreen (Chinese/English) for intuitive parameter control (strip lengths: front≤15mm, rear≤18mm).

Processes any wire type (30#–16# AWG) at 1,200+ pcs/hour; one-touch full-cycle automation.

We want to help you find the best option for your business. Tell us your needs by filling out the form below and we will contact you as soon as possible!