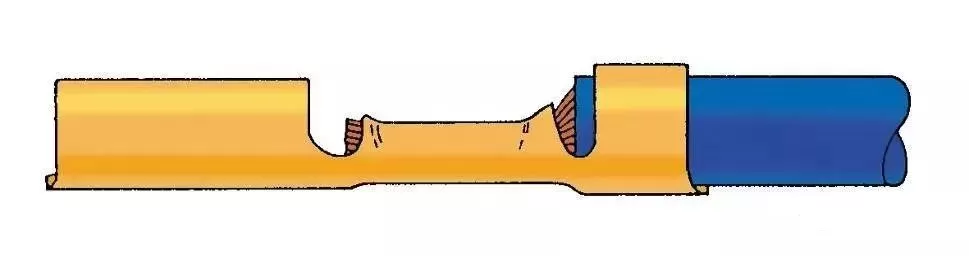

Crimping is the process of applying pressure to the contact area of the wire and the terminal to form it and achieve a tight connection.

Solderless connection technology was first proposed by AMP in 1941.

Crimping requirements

Provides an inseparable, long-term reliable electrical and mechanical connection between the crimp terminal and the wire.

The crimp should be easy to manufacture.

1 The crimping structure suitable for a specific wire diameter range and material thickness can be obtained by calculation

2 It can be used for crimping of different wire diameters only by adjusting the crimping height

3 Low cost through continuous stamping production

4 Crimp automation

5 Stable performance in harsh environments

A. Requirements for a qualified crimp:

1. Lead wire:

1) Select the wire diameter to meet the applicability requirements of the crimp terminal

2) The stripping meets the requirements (the length is suitable, the coating is not damaged, and the end is not

cracking and bifurcation)

2. Terminal

This is the last one.