Key Takeaways:

Automated wire processing achieves defect rates below 0.1%, compared to 7-10% with manual methods

Modern crimping systems use real-time force monitoring and machine vision for micrometer-level precision

Coaxial cable preparation now involves laser measurement and TDR testing for RF performance verification

Industry 4.0 integration enables predictive maintenance and process optimization through data analytics

Material science advancements in terminal alloys and plating technologies enhance connection reliability

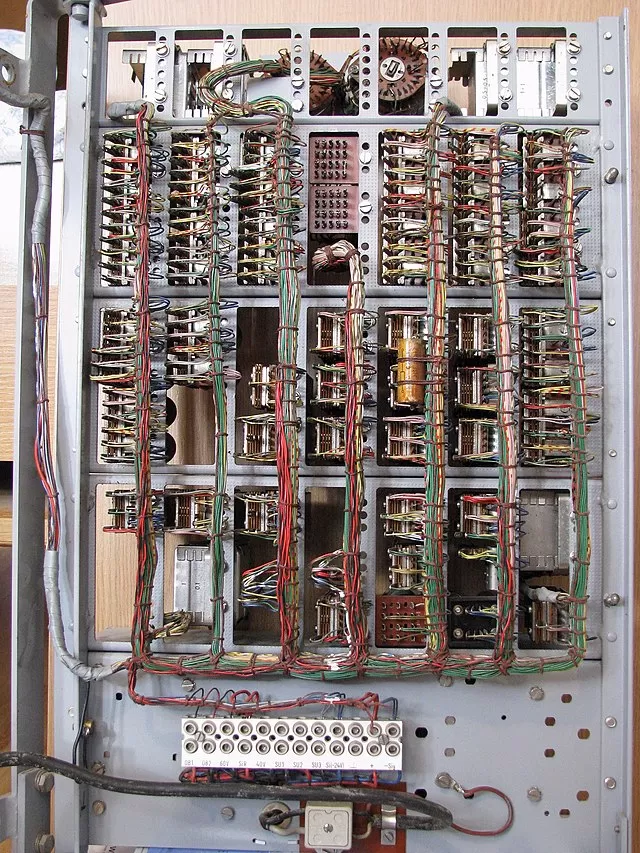

Wire processing forms the vital circulatory system of modern electronics, where precise connections ensure the lifeblood of electrical signals flows reliably. As Industry 4.0 transforms production lines, the manual methods that once dominated wire harness assembly struggle to meet the stringent consistency requirements of today's aerospace, automotive, and telecommunications equipment. The shift toward automation in wire processing isn't simply about speed - it's about achieving microscopic precision at scale while capturing the data needed for continuous improvement.

What appears as a simple metal compression actually involves sophisticated physics when performed at industrial scale and precision. Modern automated crimping systems, ranging from advanced semi automatic wire crimping machine setups to fully automated lines, must account for material springback, terminal plating variations, and copper's work hardening characteristics - all while maintaining cycle times under two seconds. The best systems today incorporate self-learning algorithms that automatically adjust for tool wear and material lot variations, achieving reject rates below 0.1% even with mixed production runs. This reliability comes from multiple redundant monitoring systems: laser micrometers verify terminal dimensions before crimping, force sensors track the complete pressure curve during operation, and high-resolution cameras inspect each completed connection from multiple angles. The data from these systems doesn't just ensure quality - it builds predictive maintenance models that can forecast tool replacement needs weeks in advance.

Processing coaxial cables for high-frequency applications requires understanding electromagnetic field theory as much as mechanical engineering. The transition region where cable meets connector forms a critical impedance interface that can degrade signals if not perfectly prepared. Automated systems now achieve this through multi-stage processes that combine mechanical precision with advanced sensing. First, lasers map the cable's outer diameter and concentricity to within 5 micrometers. Then, servo-controlled blades execute precision cuts using variable speed algorithms that change based on the dielectric material - slower for foamed polyethylene to prevent compression, faster for solid PTFE to ensure clean edges. The final inspection stage often incorporates time-domain reflectometry (TDR) to actually test the prepared cable's signal reflection characteristics, verifying the assembly will perform in the field.

The true power of automated wire processing emerges when systems connect to broader manufacturing execution systems. Modern equipment generates terabytes of process data annually - from detailed force curves for every crimp to micrometer-level measurements of stripped lengths. Forward-thinking manufacturers now analyze this data to uncover hidden relationships between processing parameters and field failure rates. One automotive supplier discovered that cables processed during certain humidity ranges showed different long-term reliability, leading to climate control improvements in their factory. The Industry 4.0 revolution also enables flexible production scheduling, where wire processing machine automatically adjusts to urgent orders or material shortages without human intervention. This level of responsiveness will become increasingly vital as product lifecycles continue accelerating across all industries.

The quiet revolution in wire processing automation represents one of manufacturing's most significant quality transformations in recent decades. By combining precision mechanics with data science and materials engineering, modern systems deliver reliability that manual methods simply cannot match - while providing the traceability and flexibility demanded by today's fast-evolving industries. As connectivity becomes ever more critical across all technology sectors, the automatic wire processing machine will form the foundation for our electrified future.

James Wilson

Senior Process Engineer | Wire Processing Specialist

With over 15 years' experience in automotive and aerospace wire harness manufacturing, James has led automation projects for major OEMs. His expertise spans the complete wire processing value chain - from conductor metallurgy to Industry 4.0 integration strategies. James now consults for manufacturers transitioning to smart wire processing systems. He holds patents in high-speed crimp monitoring and predictive maintenance algorithms for wire processing equipment.

References [1] M. Kaufmann and J. Meier, Automated Wire Processing for Industry 4.0, 2nd ed. Berlin: Springer, 2022, pp. 45-78.

[2] A. Rodriguez et al., "Machine vision systems for crimping quality control," IEEE Trans. Ind. Electron., vol. 68, no. 4, pp. 3421-3432, Apr. 2021.

[3] International Wire Harness Association (IWHA), Global Standards for Automated Cable Assembly, Geneva: IWHA Press, 2023.

[4] S. Chen and H. Yamamoto, "TDR applications in RF cable testing," J. Electron. Manuf., vol. 29, no. 3, pp. 185-197, 2020.

[5] TE Connectivity White Paper, "Material science advancements in terminal alloys," TE-2022-WP-114, June 2022.

This is the last one.